Automatic data capture just got a new ally, the edge. The technology allows everything from scanners to voice systems to process data on the edge of where it is collected. The result is real-time decisions that deal with reality, not some plan that no longer applies.

01.17.22

By Gary Forger

It’s got to be here somewhere. Stop for just a minute. Let’s look around. It shouldn’t be that difficult to find the edge in materials handling operations. But then again, maybe it is.

What exactly is the edge? Where is it? Why does it matter? These are all good questions, especially if someone has told you only IT needs to know or care about edge. They’re wrong. And just for the record, we’re not talking Microsoft Edge on your laptop.

What we are talking about is data collection with automatic data capture (ADC) hardware from scanners to mobile terminals and voice systems as well as a proliferation of sensors that track everything from vibrations to temperatures in the plant and warehouse. Processing all of this data is becoming edge enabled, and the momentum for bringing edge into day-to-day operations is building.

Two years ago, edge wasn’t much of a consideration. But that’s changed lately.

Capturing data gets done at key decision-making points in your operations. These new edge capabilities allow the data capture hardware to either make or strongly influence operational decisions at that point, without communicating with the Cloud.

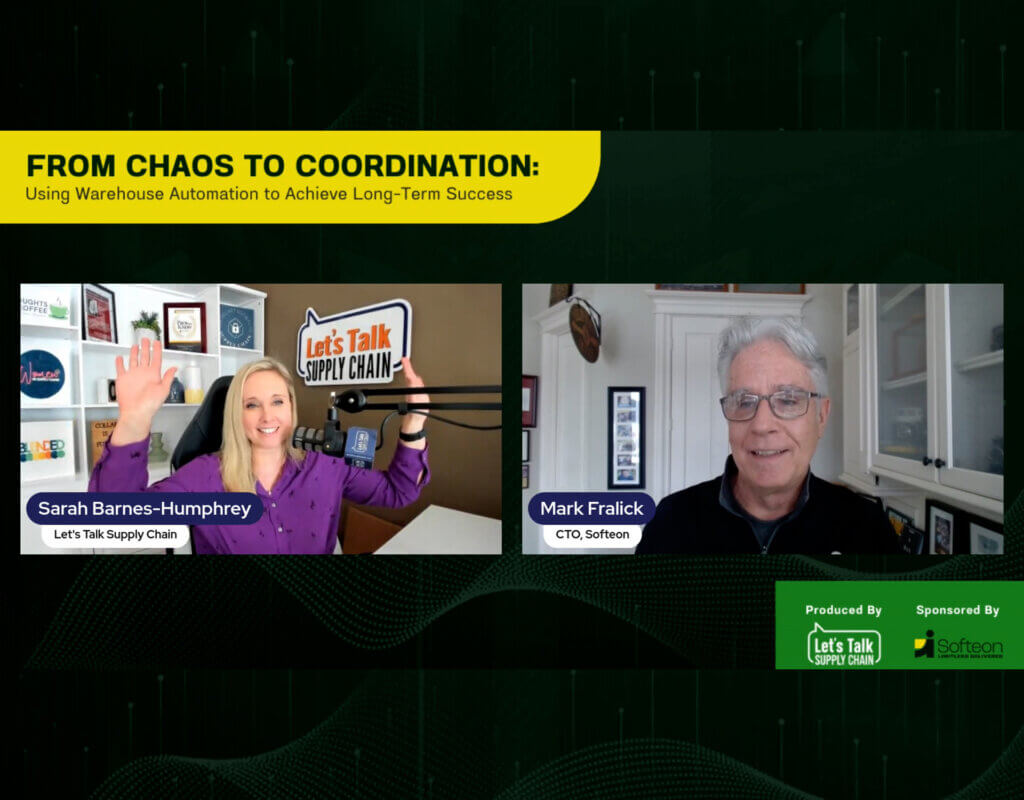

“General data capture in DCs is not much different than it was 20 years ago,” says Dan Gilmore, chief marketing officer at Softeon. “But we’re moving to an era of not just capturing and validating distribution center transactions, but to leveraging the technology and data captured to identify dwell times and delays, and provide a data platform for making distribution decisions faster.” There’s no operations manager who wouldn’t see that as significant and helpful.

Full Story

Source: Modern Materials Handling Magazine