09.15.20

Following these guidelines can boost your chances for a successful WMS implementation.

While warehouse management systems can provide many benefits, implementing one carries risks.

“A WMS can put a company out of business if it’s the wrong vendor or solution, or it can propel a business

ahead of the competition,” says John Reichert, senior director, SCE solutions with Tecsys, a supply chain technology provider. Follow these steps for successful WMS implementation:

1. KNOW WHEN YOU NEED A WMS.

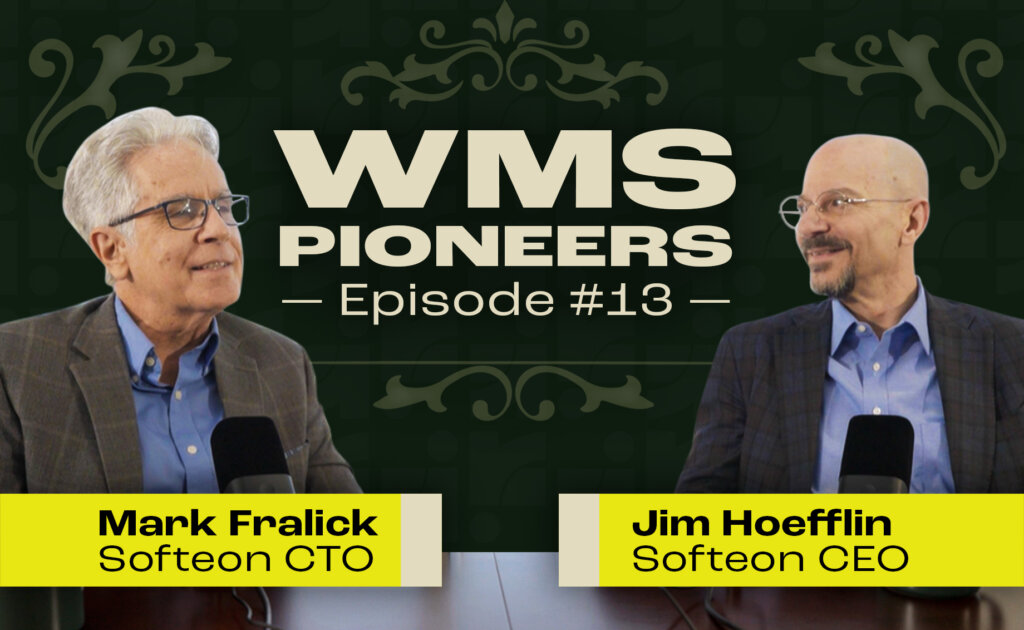

Size can influence the need for a WMS; larger operations are more likely to benefit from a solution. However, warehouse complexity, which generally results from the types of units handled and the number of processes, more often drives the decision, says Dan Gilmore, chief marketing officer with Softeon, a supply chain solutions provider.

The “eaches” picking, typical with e-commerce sales, tends to be more complex than pallet operations. Similarly, multiple product types—say, a mix of those requiring refrigeration or freezing—also boosts complexity.

Source: Inbound Logistics, authored by Karen Kroll